Self-Propelled Forage Harvesters

We offer application systems for Self-Propelled Forage Harvesters which can be used with water soluble or premixed products. Our Dohrect Enject Systems are exclusively designed for Low Volume, Concentrate application of water soluble, bacterial based products (inoculants) on Forage Harvesters. Our Ag-Serv Applicators can be used for pre-mixed preservatives or water soluble products at higher application rates

Dohrect Enject Systems

DE-1008.5 Dohrect Enject Applicator

Our

Dohrect Enject

Systems were the original "Low Volume, Long Distance" application system for concentrate water soluble inoculants, introduced in 2001. These systems have a proven record of dependability and are known for being easy to use and simple to clean and maintain. The DE-1008.5 was introduced in 2014, replacing the original DE-1000. Every DE-1008.5 applicator goes through our stringent Quality Control Process before it is packaged and shipped. Check out our DE-1008.5 Quality Control video.

DE-1008.5

Dimensions: 23 1/4" L x 16 1/2" W x 23 1/4"

Includes:

- 10 gallon insulated cooler

- Mix up to 1000 treatable tons in only 10 gallons

- Prevents "greenhouse effect" in the tank, keeps the solution cool throughout warm weather. This means more active bacteria towards the end of a long day which gives you the best ROI

- Keeps bacteria "healthy" longer in the event of breakdown or rainout-protecting your investment

- Tank is easy to remove and has a large lid opening so it is easy to clean

- Pump Unit - Assembled and tested in-house

- Capable of treating up to 8.5 Tons per Minute (510 Tons per Hour): spec-built pump with components compatible with water soluble inoculant bacteria

- Application rates (per ton) as low as 1.28 fl. Oz

- Push to disconnect fittings makes it easy to replace a pump tube

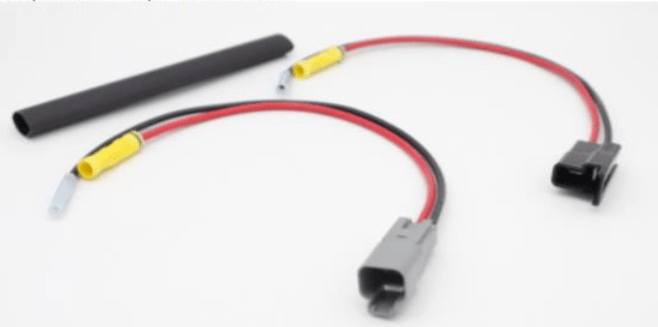

- Wire Harness - Built and tested in-house

- Pre-Terminated, no need to cut and splice wiring

- Mating terminals for SP-2L Speed Control (Included in DE-1008.5)

- "Plug & Play"

- Stainless Steel Components - Rust resistant

- The pump enclosure, baseplate, pump mount brackets and pump support bracket are all stainless steel

- Distribution System

- The system has straight through flow path without nozzles or orifice to minimize plugging

- Easy to Maintain

- Push to disconnect fittings on Pump Tube, Flush Bottle and Cooler Valve Assembly fittings which make changes tubes fast and easy to change

- Built-in 32 oz. clean water flush system

- SP-2L Variable Rate Controller

- Built-In On/Off Switch

- Allows application rate to be changed by adjusting the dial for changing harvest conditions

- Made exclusively for the Dohrect Enject Systems. Contains an additional output to power the LED illumination of the FM-1008.5-LED Flowmeter

- LED Status Indicator

- 3 year warranty (for more information, click here)

- FM-1008.5-LED Illuminated Flowmeter

- Custom calibration scale for products ranging from 1-2 grams/ton and 100K-200K bacteria count

- Simple indication of calibration output as well as flow indication

- Measurement in Tons per Minute (100 tons per gallon rate) and ounces per minute

- Is illuminated so the operator can verify calibration and system performance during night harvest

- Lifetime Support

- 1 Year Applicator Warranty

Additional Options

#190000

"Header Switch" wiring adapter for John Deere Self-Propelled Forage Harvesters (SPFH); 7000, 8000 & 9000 Series. This can be used in place of John Deere Part #AZ100126

If You're Looking For The Ability To Have More Inoculant On The Go, Consider...

DE-1008.5X2

This is the complete DE-1008.5 system with a second tank, base plate, and a selection manifold.

If you already have a DE-1008.5, but would like the additional capacity, simply order item:

X2-1008.5-KIT

This adds a secondary insulated tank, base plate, and selection manifold to the applicator to allow the operator to treat up to 2000 tons per fill.

Ag-Serv Applicators - Conventional Application

These units are built in-house and every applicator goes through a stringent quality control process before leaving our facility. Check out our AgServ Quality Control video.

DE-100

Dimensions:

Tank & Frame: 57"L x 24"W x 31"H

Pump Unit: 15"H x 15"W x 6.5"D

Includes:

- 100 Gallon Capacity Tank with flat surface mounting brackets

- Pump Unit - Assembled and fluid tested in-house

- 3.0 GPM self-priming, spec-built pump with wetted components compatible with acid based and acid producing products with a pH as low as 4

- Filter Assembly before the pump to protect the pump unit components and nozzles. Filter screen can be removed and cleaned

- Pressure Regulation System allows fine tuning of pressure and circulation back to the tank

- Stainless Steel Gauge - Internals, Externals, & Port to be most compatible with the acid-based and acid-producing products commonly found in our industry

- Self-Fill System. You can connect the included Fill Stem Assembly to the pump unit to use the applicator pump to refill its tank

- Wire Harness - Built and tested in-house

- Pre-Terminated, no need to cut and splice wiring.

- 3 Nozzle Assembly with 20' of hose

- Includes a variety of nozzle sizes that cover calibration for most product applications

- 4" In-line Gauge Assembly

- Large 4" gauge which is easy to ready, mounts in the pressure line between the pump unit and nozzles (some applications the pump unit may not be able to be viewed)

- Stainless Steel Gauge - Internals, Externals, & Port to be most compatible with the acid-based and acid-producing products commonly found in our industry

- SP-1 Speed Control

- Built-In On/Off Switch

- Allows application rate to be changed by adjusting the dial for changing harvest conditions

- LED Status Indicator

- 3 year warranty (for more information,

click here )

- Lifetime Support

- 1 Year Applicator Warranty

DE-55

Dimensions

Tank & Frame: 38"L x 23"W x 32"H

Pump Unit: 15"H x 15"W x 6.5"D

Includes:

- 55 Gallon Capacity Tank with flat surface mounting brackets.

- Pump Unit - Assembled and fluid tested in-house

- 3.0 GPM self-priming, spec-built pump with wetted components compatible with acid based and acid producing products with a pH as low as 4

- Filter Assembly before the pump to protect the pump unit components and nozzles. Filter screen can be removed and cleaned

- Pressure Regulation System allows fine tuning of pressure and circulation back to the tank

- Stainless Steel Gauge - Internals, Externals, & Port to be most compatible with the acid-based and acid-producing products commonly found in our industry

- Self-Fill System. You can connect the included Fill Stem Assembly to the pump unit to use the applicator pump to refill its tank

- Wire Harness - Built and tested in-house

- Pre-Terminated, no need to cut and splice wiring

- 3 Nozzle Assembly with 20' of hose

- Includes a variety of nozzle sizes that cover calibration for most product applications

- 4" In-line Gauge Assembly

- Large 4" gauge which is easy to ready, mounts in the pressure line between the pump unit and nozzles (some applications the pump unit may not be able to be viewed)

- Stainless Steel Gauge - Internals, Externals, & Port to be most compatible with the acid-based and acid-producing products commonly found in our industry

- SP-1 Speed Control

- Built-In On/Off Switch

- Allows application rate to be changed by adjusting the dial for changing harvest conditions

- LED Status Indicator

- 3 year warranty (for more information, click here)

- Lifetime Support

- 1 Year Applicator Warranty